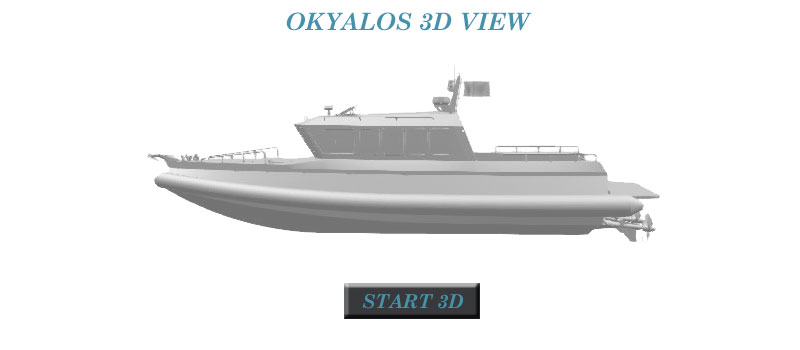

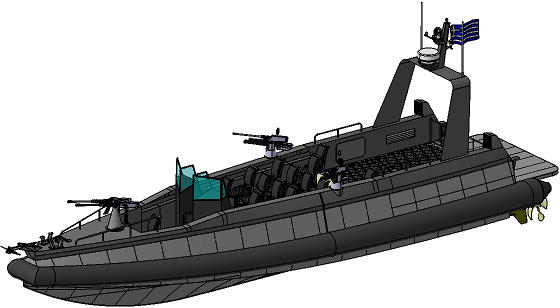

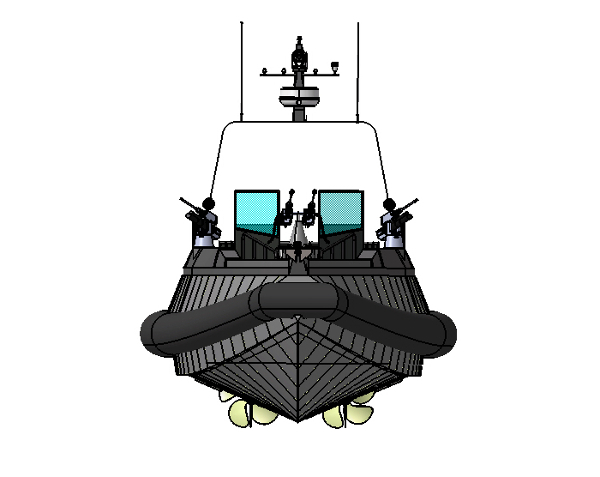

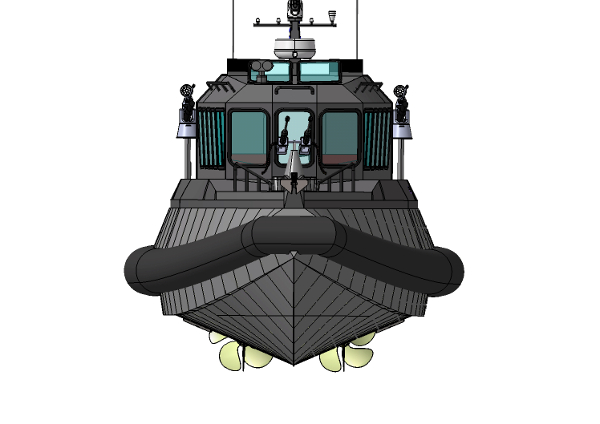

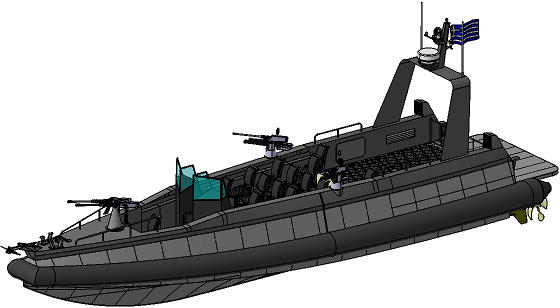

"Okyalos Οpen 14" & "Okyalos Closed 10"

Two high speed vessels which can be very easily

used for military purposes because of their characteristics

and armament they can carry.

Their development is based on the prototype launched,

tested and adopted by Hellenic Navy on June 2015.

The performance and propulsion system will be defined

in cooperation with Volvo Penta and Twin Disk.

Their basic advantage lies on the adaptability to the

client’s needs even during even during manufacturing phase

(customized design).

More details:

| Applications / Use cases |

OKYALOS is characterized by its plurality of comparative advantages in relation to ribs or different material boats |

- Sea Border Surveillance and Patrolling

- Broad Land and Sea Areas Surveillance

- Coastal & Maritime Surveillance

- Critical Infrastructure Inspection

- Physical Disasters Monitoring

- First Responders / Emergency Management

- Search & Rescue Operations Support

- Sea Traffic Surveillance

- Anti-Terrorist and Law Enforcement Operations Support

- Anti-Smuggling Surveillance

- Natural Resources Monitoring

- Scientific Research

- Damages and Natural Disasters Assessment

- Emergency Personnel Response / Rapid Personnel Evacuation

- Teams Transportation (e.g. special forces teams)

- Force / convoy protection

- Marine Safety

- Communications relaying

- Communications Intelligence (COMINT) / Electronic intelligence (ELINT)

- Electronic Warfare (EW)

|

- Manufactured with the top quality aluminum used worldwide of shipbuilding

- Classified by Bureau Veritas (BV)

- A miniature frigate (frigate capabilities at a flexible size, with respectively low functional and maintenance costs)

- Fine design and shipbuilding by technology-artists engineers

- Customization capabilities which allow uncomplicated changing of equipment, purpose, applications

- Long-time lifespan (min 30years)

- Bulkheads that mitigate the possibility of sinking

- A set of inflatable tubes surrounds its aluminum hull, which adds to its stability and seaworthiness, while being very helpful for touch n go or divers pickup operations

- Inboard engines (professional, reliable, diesel, of greater horsepower and lower maintenance cost)

- Optimal selection of thrust system adapted from racing crafts

- Special design anti-vibration seats so to ease fatigue over long top speed cruises with technology adopted from racing off road motorbikes.

- Separately installed, easily removable, aluminum fuel tanks.

- Quick & easy damage repair/inspection (or battle damage repair for military versions)

- Manufactured in Europe

|

| Why Aluminum? |

| Life Limit |

Weight Fuel Speed |

- Corrosion Resistant

- Low Maintenance Cost. Checking the condition and changing sacrificial anodes (zinc or magnesium) regularly, the structure can be protected from the corrosive environment.

- The naval alloys 5000 and 6000 series are known for their high strength, corrosion resistance, and good elasticity.

- An aluminum boat is estimated to have a life span of more than 30 years.

|

- The low density of aluminum, combined with high strength, toughness, and corrosion resistance, allow vessel designers to achieve weight savings of 20-30% over GRP designs.

- Weight savings equate to higher speed and less fuel consumption.

|

| Impacts |

Sun Exposure |

- GRP material is extremely brittle while aluminum has considerable ductility.

- In case of strong impacts, the GRP may face cracking and fracture while aluminum can support impact loads without detrimental permanent deformation.

|

- Aluminum is not affected by Ultraviolet (UV) radiation while GRP ages over the time increasing the point of brittleness. The higher the brittleness, the higher the possibility of cracking in case of impacts.

|

| Recyclability |

Fire Resistance |

- Over two-thirds of all the aluminum ever produced is still in use today.

- GRP cannot be recycled at all.

|

- GRP boats contain petroleum based resins which are flammable. In order to face the problem of fire, fire retardant resins are used to make fire more difficult to start.

- Aluminum is described as non-combustible (British Standard BS476). The same set of standards gives aluminum high marks on the fire resistance versus spreading scale.

|

| Delamination |

Maintenance |

- Many GRP boats are often not constructed in well controlled temperature buildings leading to the widespread problem of fiberglass pox.

- Affects negatively boats' life.

- The life time of an aluminum boat is about double that of the GRP.

|

- Aluminum boats are preferred in hard jobs because the repair procedure is easy and quick.

- Widespread use (Military, Landing crafts, Lifeguards and many Fishing boats are made from aluminum) because a small scratch or hitting can be fixed in a few minutes.

|

| Raw Material Origin |

- Superior quality, most extensively used in shipbuilding worldwide, produced in Greece aluminum is used.

|